PVD fa'apipi'i

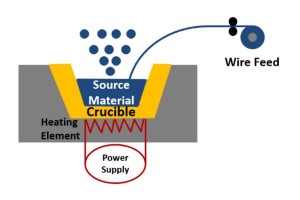

PVD (Physical Vapor Deposition) tekinolosi e faasino i le faʻaogaina o metotia faʻaletino i lalo o tulaga gaogao e faʻafefe ai luga o se puna mea (malosi poʻo vai) i totonu o kasa kasa poʻo mole mole, poʻo se vaega o le ionize i ions, ma e ala i se kasa maualalo (maualalo). po'o le plasma) fa'agasologa, O se tekonolosi e teu ai ata manifinifi ma ni galuega fa'apitoa i luga o se mea'ai.PVD (Physical Vapor Deposition) o se tekonolosi togafitiga autu o loʻo faʻaaogaina lautele i le faʻaleleia o luga, faʻatinoga, teuteuga, ma isi mea i totonu o pisinisi eseese.

O le PVD (faʻapipiʻi ausa faʻaletino) tekinolosi faʻapipiʻiina e masani ona vaevaeina i ni vaega se tolu: faʻamalo faʻamalo, faʻapipiʻi faʻafefe, ma faʻapipiʻi ion.O auala autu o le teuina o le ausa faʻaletino e aofia ai le faʻafefe o le gaogao, faʻapipiʻiina o le paʻu, faʻapipiʻi arc plasma, faʻapipiʻi ion, ma isi mea.

O a matou oloa faʻatatau e aofia ai laina eletise eletise, filaments evaporation tungsten, filaments tungsten fana eletise, vaʻa faʻasao, mea e faʻafefe ai mea, faʻamaʻi sini, ma isi.

Ogaumu Vacuum

O se ogaumu gaogao e faʻaaogaina se masini faʻamama (faʻapipiʻi ma le faʻaeteete mai pamu mama, masini e fua ai, vacuum valves, ma isi vaega) i totonu o se avanoa faapitoa o le ogaumu e faʻafefe ai se vaega o mea i totonu o le ogaumu ina ia oʻo ai le mamafa i totonu o le ogaumu. lua e itiiti ifo ma le tasi le mamafa masani o le ea., o le avanoa i totonu o le ogaumu o loʻo faʻaaogaina e ausia ai se tulaga faʻafefe, o se ogaumu gaogao.

O le ogaumu mama o se ogaumu vevela vevela vevela, lea e iloga e tusa ai ma lona faʻaogaina ma e aofia ai ituaiga nei:

Ogaumu fa'avevela, ogaumu fa'amama fa'amama, ogaumu fa'afefeteina, ogaumu fa'amaneta, ogaumu fa'afefete, ogaumu fa'ameamea, ogaumu fa'afefete, ma isi.

O ogaumu masima e masani ona faʻaaogaina mo le faʻafefeina o le sima, faʻafefeteina faʻafefe, vaega eletise eletise degassing, annealing, faʻamauina o vaega uʻamea, faʻamaufaʻailoga uamea-mea, faʻapipiʻi ausa faaletino (PVD), ma isi.

Matou te ofoina atu elemene faʻavevela, Faʻailoga Vaʻa ma Taʻavale, talipupuni vevela, crucibles ma liners, filaments tungsten ma puna faʻasao, faʻamau, ma isi mea, e maua i tungsten, molybdenum, poʻo mea tantalum, ma e mafai ona faʻapitoa.

Photovoltaic & Semiconductor

O se ogaumu tuputupu aʻe o le silicon-crystal, e lauiloa foi o le silicon crystal growth furnace poʻo le silicon ingot furnace, o se meafaigaluega faʻapitoa e faʻaaogaina i le photovoltaic ma semiconductor alamanuia e maua ai le maualuga o le tasi-crystal silicon ingots.Monocrystalline silicon o le mea autu mo le gaosiga o masini semiconductor e pei o fesoʻotaʻiga tuʻufaʻatasia (ICs), solar cell, ma masini.

O le "Czochralski method" o le taimi nei o le auala sili ona faʻaaogaina mo le sauniaina o le silikoni tioata tasi.

Pe a saunia le silicon tasi-crystal e faʻaaoga ai le Czochralski method (CZ method), tuʻu muamua le silikoni polycrystalline maualuga-mama i totonu o se quartz crucible, faʻatali mo le polycrystalline silicon e liusuavai i totonu o se ogaumu tioata tasi, ona faʻapipiʻi lea o le tioata fatu i luga o fatu. axis ma faʻapipiʻi i luga o le vaifofo.O le faʻatali mo le tuʻufaʻatasia o le tioata fatu ma le vaifofo, o le a amata ona faʻamalosi le silicon i luga o le tioata fatu ma ola i luga o le lattice structure o le tioata fatu e fausia ai le silicon-crystal silicon.I le faagasologa o lenei faagasologa, e tatau ona toso lemu le tioata o fatu ina ia mafai ai ona tuputupu aʻe le silikoni tasi-kristal.

Matou te tuʻuina atu fatu fatu molybdenum, tungsten ma molybdenum crucible liners, faʻamau, matau molybdenum, samala tungsten carbide, ma isi.

tioata ma eleele seasea

O le alamanuia tioata e iai sona sao taua i sosaiete faʻaonaponei, tuʻuina atu mea taua mo le fausiaina, felauaiga, tekinolosi, soifua maloloina, ma le afifiina aʻo faʻatautaia mea fou, faʻaauau, ma le tuputupu aʻe o le tamaoaiga.

E mafai ona tatou saunia molybdenum electrodes mo tioata liusuavai.E masani ona faʻaaogaina molybdenum electrode diameters mai le 20mm i le 152.4mm, ma le umi o se electrode tasi e mafai ona oʻo atu i le 1500mm.E mafai ona matou tuʻuina atu mea faʻapipiʻi alkali, masini faʻalelei, ma isi.

O le alamanuia o le eleele e le masani ai e aofia ai le faʻaaogaina, faʻaogaina, ma le faʻaogaina o elemene eleelea e le masani ai, ia e taua i le faʻalauiloaina o tekonolosi fou ma lagolagoina le suiga i se tamaoaiga maualalo-carbon, maualuga-tekonolosi.O elemene o le eleele e seasea maua o ni vaega taua o tekinolosi ma fa'aoga eseese.

E mafai ona matou tuʻuina atu elemene faʻavevela tungsten, molybdenum, ma tantalum;tungsten sintered, molybdenum crucibles ma graphite crucibles, ma isi.

Meafaigaluega & Meter Mea'ai

● O fa'ameamea u'amea e masani ona fa'aaogaina i fa'amau fa'amau ma transmitters.O mea matou te gaosia e aofia ai SS316L, tantalum, titanium, HC276, Monel400, ma Inconel625.

● Faʻailoga eletise e masani ona faʻaaogaina i mita eletise eletise.Ole tele ole eletise ole M3 ~ M8, ma o mea e aofia ai SS316L, tantalum, titanium, ma le HC276.

● Ground Electrode, e taʻua foi o le mama o le eleele, e masani ona faʻaaogaina i masini eletise eletise ma e masani ona faʻaogaina i paga.Ole tele e mai le DN25~DN600, ma o mea e aofia ai SS316L, tantalum, titanium, ma le HC276.

● Flange fa'amaufa'ailoga diaphragm, e masani lava ona i ai se fa'amaufa'ailoga diaphragm e fa'aesea ai le sela fua mai le ala.Flange mea matou te gaosia o SS316L, Titanium, HC276, ma Tantalum.Ia tausisia ASME B 16.5, DIN EN 1092-1, ma isi tulaga.

E te fia iloa atili e uiga ia matou oloa?

Faafesootai matou

Amanda│Pule Fa'atau

E-mail: amanda@winnersmetals.com

Telefoni: +86 156 1977 8518 (WhatsApp/Wechat)

Afai e te fia iloa atili faʻamatalaga ma tau oa matou oloa, faʻamolemole faʻafesoʻotaʻi le matou pule faʻatau, o le a ia tali atu ia te oe i se taimi vave e mafai ai (e masani lava e le sili atu i le 24h), faafetai.